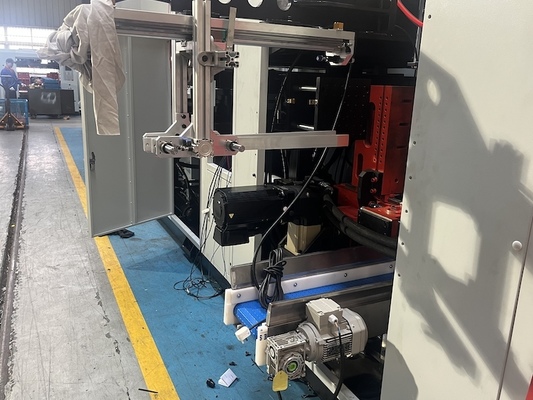

HDPE LDPE PP MP75FD Automatic Blow Moulding Machine

Product Description

The Automatic Blow Moulding Machine is industrial equipment designed for producing hollow plastic items, playing a crucial role in manufacturing bottles, containers, jars, and tanks. The process involves heating plastic material until pliable, then using compressed air to expand it into the mould's shape, ensuring consistent and precise final products. Automation enhances production efficiency and maintains high-quality standards in hollow plastic goods manufacturing.

Key Features

Fully Automatic Operation: Reduces labor costs with automatic preform loading, heating, blowing, and bottle ejection processes.

High Production Capacity: Multi-cavity options (2-12+ cavities) produce 1,000-20,000 bottles/hour for medium to large-scale production.

Consistent Quality: Precise control of heating temperature, stretch ratio, and blowing pressure ensures uniform wall thickness and high clarity.

Energy Efficient: Infrared heating system and servo-driven components reduce power consumption with zoned heating technology.

Versatile Moulding: Quick mould-switching system supports various bottle types (beverage, oil, cosmetic, pharmaceutical).

User-Friendly: PLC touchscreen interface with error diagnosis and automatic alarms for easy operation and maintenance.

Wide Applications: Produces PET, HDPE, and PP bottles for diverse industries including beverages, chemicals, and pharmaceuticals.

24/7 Operation: Designed for continuous production, integrating seamlessly with filling, labeling, and packing lines.

Technical Specifications

| Parameter |

MP75FD φ80 |

| Material |

PE PP |

| Max Container Capacity (L) |

0.1 |

| Number of Die (Set) |

4 |

| Machine Dimensions (L×W×H) (M) |

3.6×2.2×2.36 |

| Total Weight (Ton) |

5.5 |

| Clamping Force (KN) |

120 |

| Platen Opening Strokes (mm) |

180-480 |

| Toggle Stroke (mm) |

300 |

| Max Mould Size (W×H) (mm) |

460×450 |

| Screw Diameter (mm) |

80 |

| Screw L/D Ratio (L/D) |

24 |

| (HDPE) Plasticizing Capacity (kg/h) |

100 |

| Screw Heating Zone (zone) |

4 |

| Screw Heating Power (kw) |

15.85 |

| Fan Power (kw) |

0.28 |

| Extruder Driving Power (kw) |

30 |

| Die Head Heating Zone (zone) |

3 |

| Power of Die Heating (kw) |

8 |

| Power of Electric Motor (kw) |

11 |

| Air Pressure (Mpa) |

0.6-0.8 |

| Total Power of Machine (kw) |

65.13 |

| Average Energy Consumption (kw) |

31 |

| Compression Air Consumption (m3/min) |

1.2 |

| Cooling Water Consumption (L/min) |

40 |

Applications

Beverage Packaging: Mineral water, juice, carbonated drinks, and tea bottles.

Food Packaging: Edible oils, dairy products, and condiment containers.

Household & Personal Care: Detergents, shampoos, shower gels, and cosmetic products.

Pharmaceutical: Medicine bottles and nutritional supplement containers.

Chemical & Industrial: Lubricant oils, pesticides, and large plastic drums.

Home & Daily Use: Plastic toys, jugs, and storage containers.

Medical & Healthcare: Disinfectant and medical spray bottles.

Custom Packaging: Prototype designs and premium cosmetic bottles.

Customization Options

MEPER offers customized MP75FD Automatic Blow Moulding Machines with CE and ISO9001:2008 certification. Features include an 80mm screw diameter, 6kw screw heating capacity, and In Mold Labeling (IML) technology. Standard export packaging ensures safe delivery within 25-35 work days, with flexible payment terms (L/C, T/T) and a supply capacity of 100 sets/month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!