Product Description:

One of the key features of this Automatic Blow Moulding Machine is its customizable color. You can choose the color that best suits your needs, making it easy to integrate into your existing production line. Additionally, this machine comes with a 1-year warranty, giving you peace of mind and ensuring that you can get the most out of your investment.

Another important aspect of the Automatic Blow Moulding Machine is its contactor. This machine is equipped with a Schneider contactor, which is known for its durability and reliability. This ensures that your machine will operate smoothly and efficiently, minimizing downtime and maximizing productivity.

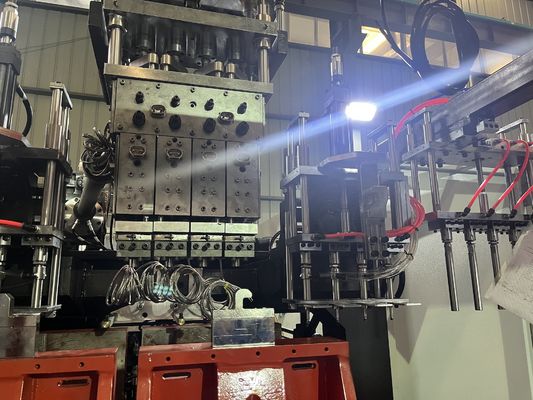

The Automatic Blow Moulding Machine uses extrusion blow molding technology, which is ideal for producing high-quality plastic products. With this technology, you can create products with consistent wall thickness and excellent surface finish, ensuring that your products look and perform their best.

The clamping system of this machine is a toggle type clamping system. This system is highly efficient and provides a high level of control over the clamping force. This ensures that your products are produced with the highest level of accuracy and precision, making them ideal for a wide range of applications.

Overall, the Automatic Blow Moulding Machine is an excellent choice for anyone looking for a reliable and efficient jerry can blow molding machine, custom blow molding machine, or 5 gallon blow molding machine. With its customizable color, 1-year warranty, Schneider contactor, extrusion blow molding technology, and toggle type clamping system, this machine is sure to meet all your blow molding needs.

Features:

- Product Name: Automatic Blow Moulding Machine

- Blow Moulding Type: Extrusion Blow Moulding

- Operation: Automatic

- Product: Milk Bottle Packing Bottle

- Blow Molding Type: Extrusion Blow Molding Machine

- Color: Customized

- Application: plastic bottle blow molding machine, pet bottle blow molding machine, water bottle blow molding machine

Technical Parameters:

| PARAMETERS |

MP80FD φ80 |

| SPECIFICATIONS |

| material |

PE |

| MAX container capacity L |

10 |

| number of die Set |

1,2 |

| machine dimension(L×W×H) M |

3.4×5.6×2.36 |

| total weight Ton |

14 |

| CLAMPING |

| clamping force KN |

150 |

| platen opening strokes mm |

240-640 |

| toggle stroke mm |

400 |

| Max mould size(W×H) mm |

580×470 |

| EXTRUDER UNIT |

|

| screw diameter mm |

80 |

| screw L/D ratio L/D |

24 |

| (HDPE)plasticizing capacity kg/h |

100 |

| screw heating zone zone |

4 |

| screw heating power kw |

15.85 |

| fan power kw |

0.28 |

| extruder driving power kw |

30 |

| DIE HEAD |

|

| die head heating zone zone |

3 |

| power of die heating kw |

10 |

| ENERGY-CONSUMPTION |

|

| power of the electric motor kw |

29 |

| air pressure Mpa |

0.6-0.8 |

| total power of machine kw |

85.13 |

| average energy consumption kw |

42 |

| compression air consumption m3/min |

1.2 |

| cooling water consumption L/minv |

80 |

|

Applications:

The MP75AE is a bottle blow molding machine that is suitable for producing various types of plastic bottles, including PET bottles. Its toggle type clamping system ensures stable and reliable operation, while its customized color option allows for branding and personalization.

One of the main product application occasions for the MP75AE is in the packaging industry. It can produce milk bottle packing bottles, as well as other types of plastic bottles used for packaging food and beverages. Its ability to produce high-quality PET bottles makes it a popular choice for companies in the beverage industry.

The MP75AE is also suitable for producing plastic bottles used in the medical industry. Its extrusion blow molding technology ensures that the bottles produced are hygienic and sterile, making them ideal for packaging pharmaceuticals and medical supplies.

Another product application scenario for the MP75AE is in the cosmetics industry. It can produce plastic bottles and containers used for packaging cosmetics, such as lotions, shampoos, and other beauty products. Its ability to produce customized bottles with different shapes and sizes makes it a versatile solution for the cosmetics industry.

The MP75AE is available for purchase with a minimum order quantity of 1 set, and its price is negotiable. It comes with a standard export package and has a delivery time of 25-35 work days. Payment terms include L/C and T/T, and the supply ability is 100 sets per month. The machine also comes with a 1-year warranty time, ensuring its reliability and durability.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!