Product Description:

Functions

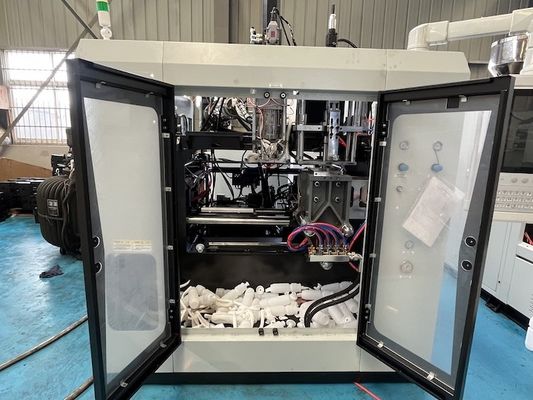

MP plastic blow molding machine is designed for processing various plastic hollow products made of high molecular materials. The machine is capable of manufacturing hollow products ranging from 5 milliliters to 100 liters in size. These products encompass a wide range of items including bottles, pots, jars, barrels, toys, tool boxes, bed boards, desk boards, chairs, and auto parts. The machine is versatile in that it not only supports the blowing of different materials such as PE, PP, PVC, PA, PC, PS, and EVA, but also ensures a flawless production process.

Features:

1.1.2 Features

a) Extruding device adopts variable frequency motor which can satisfy the requirements of rotation change of screw during blowing process. Screw with big slenderness ratio can be used to process many kinds of materials and has strong plasticizing ability, high production and low energy consumption. The barrel adopts resistance heater which is controlled by computer and heats quickly, stably, and equably.

b) By installing different head in combined extrusion system between two extrusion machines, they can blow products with view strip line or double layers.

c) Mould clamping device adopts vertical compression, three pilot post, big beam arm and linear guider, cylinder spindle and double working position. Mould moves fast and stably.

d) Improved design of hydraulic oil loop. Power saving, rapid and stable.

e) Installation and maintenance of hydraulic elements are convenient. Equipped with a removable and mobilizable oil tank.

f) The whole machine is controlled by a computer. The hydraulic system adopts double proportional control. This machine has fault automatic alarm, reliable operation, high automation and data memory of 40 sets of moulds.

g) Three operation modes - “Manual”, “Semi Auto”, “Full Auto”, are allowed to select.

h) Safety door adopts electric and mechanical safety devices (no mould closing happens when safety door opens) which make operation safe and reliable.

i) This machine has two blowing functions of straight cutting and oblique cutting.

Technical Parameters:

System Item Unit Basic Parameter

Basic specifications

Applicable materials PE PP PVC PA…

Max product volume Unit: L Value: 2

Number of heads Unit: SET Values: 1,2,3,4,5,6

Machine dimension (LxWxH) Unit: M Value: 2.87X2.14X2.28

Machine weight Unit: TON Value: 3.5

Mould clamping system

Mould clamping force Unit: KN Value: 30

Platen opening strokes Unit: MM Values: 120-350

Plate stroke Unit: MM Value: 380

Max mould sizes(WxH) Unit: MM Value: 360X300

Extrusion system

Screw diameter Unit: MM Value: 55

Screw slenderness ratio Unit: L/D Value: 24

Plasticizing ability (HDPE) Unit: KG/H Value: 45

Screw heating stage/zone Unit: Zone Value: 3

Screw heating power Unit: KW Value: 10.1

Screw fan power Unit: KW Value: 0.14

Extrusion motor power Unit: KW Value: 11

Head

Head heating stage/zone Unit: Zone Value: 5

Head heating power Unit: KW Value: 6.5

Energy consumption

Total machine power Unit: KW Value: 40

Oil motor power Unit: KW Value: 7.5

Air pressure Unit: MPA Values: 0.6-0.8

Compression air volume Unit: M3/H Values: 0.8-1

Cooling water volume Unit: L/H Value: 30

Applications:

The MEPER 5D 55d Extrusion Molding Machine is perfect for a wide range of product application occasions and scenarios. It is ideal for producing products in industries that require precision and efficiency. This machine is commonly used for 2 cavity blow moulding, auto deflashing blow moulding, and automatic extrusion blow moulding. Its versatility allows it to work with a variety of materials including PE, PP, PVC, and PA.

With a machine weight of 3.5 tons, screw diameter of 55mm, and mould clamping force of 30KN, the MEPER 5D 55d Extrusion Molding Machine is powerful and reliable. It has a maximum product volume of 2L, making it suitable for manufacturing a wide range of products. The payment terms for this machine include L/C and T/T, providing flexibility for different purchasing arrangements. Additionally, the supply ability of this machine is 100 sets per month, ensuring that it can meet the demands of various production scales.

Customization:

Product Customization Services for Molding Extruder Equipment:

Brand Name: MEPER

Model Number: 5D 55d

Place of Origin: China

Certification: CE/ISO9001:2008

Minimum Order Quantity: 1 set

Price: negotiable

Packaging Details: standard packaging

Delivery Time: 25-35 work days

Payment Terms: L/C, T/T

Supply Ability: 100 sets per month

Plate stroke: 380mm

Max product volume: 2L

Screw diameter: 55mm

Screw slenderness ratio: 24

Number of heads: 1, 2, 3, 4, 5, 6

Keywords: auto deflashing blow molding machine, 4 cavity blow moulding machine

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!