Product Description:

Functions

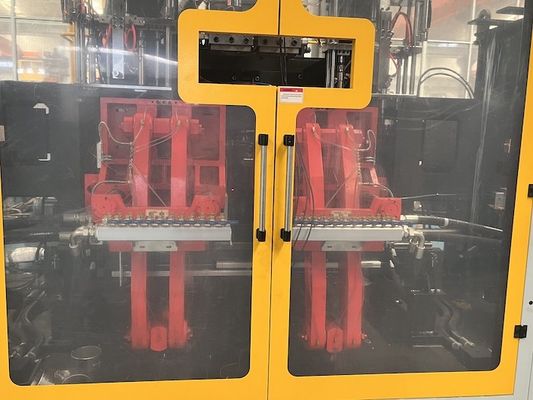

The MP plastic blow molding machine has a specialized function for processing high molecule plastic hollow products. The machine is designed to produce hollow products ranging from 5 milliliters to 100 liters and includes a variety of products such as bottles, pots, jars, barrels, toys, tool boxes, bed boards, desk boards, chairs, and auto parts, etc.

The machine is not limited to blowing just one material as it can process multiple materials such as PE, PP, PVC, PA, PC, PS and EVA. The MP plastic blow molding machine is known to provide the perfect process; resulting in impeccable products every time.

Major technical parameters

| System | Item | Unit | Basic Parameter |

Basic specifications

| Applicable materials | | PE PP PVC PA… |

| Max product volume | L | 10 |

| Number of heads | SET | 1,2,3,4 |

Machine dimension (LxWxH) | M | 4x2.3x2.5 |

| Machine weight | TON | 8.2 |

| |

Mould clamping system | Mould clamping force | KN | 150 |

| Platen opening strokes | MM | 220-620 |

| Plate stroke | MM | 540 |

| Max mould sizes(WxH) | MM | 520x460 |

| |

Extrusion system

| Screw diameter | MM | 80 |

| Screw slenderness ratio | L/D | 24 |

| Plasticizing ability (HDPE) | KG/H | 90 |

| Screw heating stage/zone | Zone | 4 |

| Screw heating power | KW | 15.85 |

| Screw fan power | KW | 0.28 |

| Extrusion motor power | KW | 30 |

| | |

Head | Head heating stage/zone | Zone | 3 |

| Head heating power | KW | 10 |

| |

Energy consumption | Total machine power | KW | 80 |

| Oil motor power | KW | 18.7 |

| Air pressure | MPA | 0.6-0.8 |

| Compression air volume | M3/min | 1.5 |

| Cooling water volume | L/min | 40 |

Applications:

The MEPER 100 FD Extrusion Blow Molding Machine has a head heating power of 10KW and a screw heating power of 15.85KW. The machine weight is 8.2t, and the cooling water volume is 40L/min. The screw diameter is 80mm.

Extrusion Blow Molding Machine is widely used in manufacturing plastic products. The MEPER 100 FD Extrusion Blow Molding Machine can be used to produce a variety of plastic products, such as plastic bottles, containers, and jars. The machine can also be used to produce plastic toys, automotive parts, and medical equipment.

The Extrusion Blow Molding Machine is suitable for a variety of materials, including HDPE, LDPE, PP, PVC, and PETG. It is an excellent choice for businesses that need to produce large quantities of plastic products quickly and efficiently. The machine is easy to operate and maintain, making it an ideal choice for businesses of all sizes.

The MEPER 100 FD Extrusion Blow Molding Machine is suitable for a variety of production scenarios, including factories, manufacturing plants, and workshops. The machine is also suitable for businesses that need to produce plastic products on a large scale, such as beverage companies, pharmaceutical companies, and cosmetic companies.

The Extrusion Blow Molding Machine is an essential tool for businesses that need to produce high-quality plastic products quickly and efficiently. The MEPER 100 FD Extrusion Blow Molding Machine is a reliable and effective choice that can help businesses meet their production needs while maintaining high quality standards.

Support and Services:

The Extrusion Blow Molding Machine product comes with technical support and services to ensure maximum efficiency and productivity. Our team of highly skilled technicians and engineers are available to provide assistance with installation, operation, maintenance, and troubleshooting. We also offer training programs to ensure that operators are able to properly operate and maintain the machines. Additionally, we provide spare parts and upgrade services to keep the machines up to date and running smoothly. Our goal is to provide our customers with the best technical support and services to ensure their satisfaction with our products.

FAQ:

Q: What is the brand name of this Extrusion Blow Molding Machine?

A: The brand name of this machine is MEPER.

Q: What is the model number of this Extrusion Blow Molding Machine?

A: The model number of this machine is 100 FD.

Q: Where is this Extrusion Blow Molding Machine manufactured?

A: This machine is manufactured in China.

Q: What certifications does this Extrusion Blow Molding Machine have?

A: This machine has CE and ISO9001:2008 certifications.

Q: What is the minimum order quantity for this Extrusion Blow Molding Machine?

A: The minimum order quantity for this machine is 1 set.

Q: What is the price of this Extrusion Blow Molding Machine?

A: The price of this machine is negotiable.

Q: What are the packaging details for this Extrusion Blow Molding Machine?

A: The standard packaging for this machine is a wooden pallet, but a wooden case is optional.

Q: What is the delivery time for this Extrusion Blow Molding Machine?

A: The delivery time for this machine is 25-35 work days.

Q: What are the payment terms for this Extrusion Blow Molding Machine?

A: The payment terms for this machine are L/C and T/T.

Q: What is the supply ability for this Extrusion Blow Molding Machine?

A: The supply ability for this machine is 100 sets per month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!