Product Description:

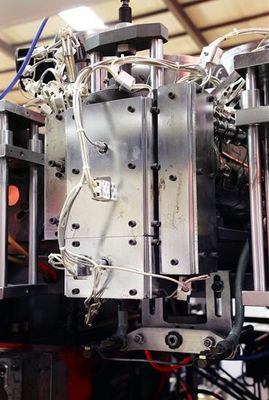

The Extrusion Blow Molding Machine (MP70FS) is a highly efficient and cost-effective extrusion blowmolding machine for producing hollow plastic products. It features a compact design, high precision and fast cycle time of 20 seconds per piece. The maximum die head is up to 4, and the clamping force is 110KN, while the total power is 50KW. This machine has been widely used in various industries, such as pharmaceuticals, cosmetics, food, and automotive, etc. It provides high-quality plastic products with superior strength, durability and aesthetic finish. The advanced design of the machine ensures efficient operation and precise control of the manufacturing process. The user-friendly interface offers an intuitive operation and easy maintenance. The optimized design of the machine ensures a high degree of safety and reliability. The Extrusion Blowing Machine is an ideal choice for those who seek high performance and cost-effectiveness in manufacturing plastic products.

Features:

Extrusion Blow Molding Machine:Weight 8.5T, Power Supply 380V/50Hz, Model MP70FS-4, Max. Product Volume 10L

Technical Parameters:

| Parameter |

Value |

| Product Name |

Extrusion Blow Molding Machine |

| Max. Product Volume |

10L |

| Material |

PP/PE |

| Power Supply |

380V/50Hz |

| Max. Mold Width |

500mm |

| Max. Mold Height |

360mm |

| Clamping Force |

110KN |

| Manufacturer |

Meper Company |

| Type |

Automatic |

| Cycle Time |

20s/pc |

Applications:

The Extrusion Blow Molding Machine is an advanced automatic processing tool used to create a wide variety of products such as plastic bottles, containers, jars and other items. It is designed to produce products with high quality and accuracy, with a maximum product volume of 10L and maximum die head of 4. It is powered by a total power of 50KW and comes with a variety of advanced features such as precise temperature control, easy operation and fast molding speed.

The Extrusion Blow Molding Machine is widely used in many industries, such as food and beverage, pharmaceuticals, cosmetics and other consumer products. It is also used for the production of industrial parts and components. With its excellent performance and reliability, this machine is widely used by manufacturers to produce products that require accurate and precise shapes and sizes.

The Extrusion Blow Molding Machine is an ideal choice for manufacturers who need to produce high-quality products in a short time frame. It can also be used for customizing products according to the customer's requirements. This machine is perfect for creating unique and complex shapes with reliable and consistent results. With its advanced features and easy operation, it is the perfect choice for any production process.

Customization:

Custom Extrusion Blow Molding Machine

Our custom-made Extrusion Blow Moulder provides a robust and efficient solution for your industrial plastic-forming needs. The Extrusion Blowing Machine comes with a total power of 50KW, and is capable of processing materials such as PP/PE. The model is MP70FS and it has a maximum mold width of 500mm and maximum mold height of 200mm.

Support and Services:

Technical Support and Service for Extrusion Blow Molding Machine

We provide technical support and service for our extrusion blow molding machine. Our experienced technical support staff are available to provide the highest level of service and support for your machine.

We provide installation and commissioning services for our extrusion blow molding machine. Our experienced technicians will install the machine and ensure it is properly set up and running optimally.

We provide maintenance services for our extrusion blow molding machines. Our technicians will inspect the machine on a regular basis and address any issues, ensuring it runs optimally.

We provide repair services for our extrusion blow molding machines. Our experienced technicians will diagnose any issues with the machine and make repairs to get it running again.

We offer training services for our extrusion blow molding machines. Our experienced trainers will provide hands-on instruction on how to properly operate the machine.

We provide parts and accessories for our extrusion blow molding machines. Our knowledgeable staff can provide the parts and accessories you need to keep your machine running.

Operation of machine

Usually operation should be processed as follows:

1) Switch on power.

2) Push heating key and begin heating.

3) Set parameter.(see “Computer Operation Manual”).

4) Use manual mode to commission machine action, to install mold and to conduct necessary adjusting.

5) Open cooling water valve. Use semiautomatic mode to trial-produce and conduct necessary adjusting.

6) After production: a). Open cooling water valve; b).Close material falling plug board; c).Vent all residual material in barrel; d). Clean material barrel( use polystyrene to clean decomposed material); e). Close electrothermal switch; f).Use manual mode to close and open mould to free situation; Stop oil pump motor; g). Switch off power.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!