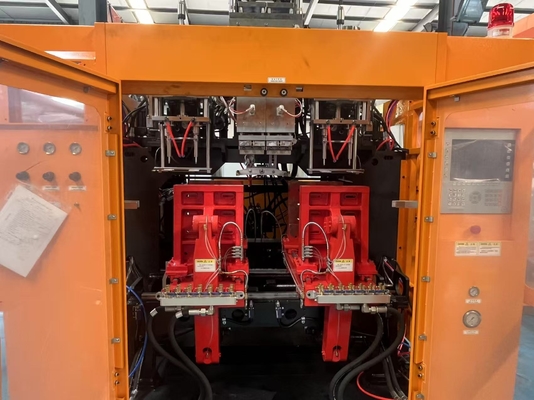

Product Description:

MP Plastic Blow Molding Machine is designed for the processing of various plastic hollow products with high molecular weight. This advanced machine is capable of producing hollow products ranging from 5 milliliters to 100 liters. The wide range of products that can be manufactured using this machine includes bottles, pots, jars, barrels, toys, tool boxes, bed boards, desk boards, chairs, and auto parts.

The versatility of the MP plastic blow molding machine allows it to work with a variety of materials, including PE, PP, PVC, PA, PC, PS, and EVA. It ensures a perfect manufacturing process, meeting the diverse needs of different industries.

Features:

a) Extruding Device: The extruding device features a variable frequency motor that enables the screw to adjust its rotation during the blowing process. It is capable of using a screw with a high slenderness ratio to process various materials efficiently, with excellent plasticizing capabilities, high production output, and low energy consumption. The barrel is equipped with a resistance heater that is computer-controlled, ensuring quick, stable, and uniform heating.

b) Combined Extrusion System: By installing different heads in the combined extrusion system between two extrusion machines, it can produce products with a view strip line or double layers.

c) Mould Clamping Device: The mould clamping device utilizes a toggle type and linear guider design. It is a double station system that facilitates faster and more stable movement of the mould platen.

d) Hydraulic Oil Loop: The machine has an improved design of the hydraulic oil loop, offering power saving, rapid response, and stable performance.

e) Hydraulic Elements: The installation and maintenance of hydraulic elements are convenient, with a removable and mobilizable oil tank included for easy access.

f) Computer Control: The entire machine is controlled by a computer, with a hydraulic system that adopts double proportional control. It features fault automatic alarm, reliable operation, high automation, and memory storage for up to 40 sets of mould data.

g) Operation Modes: The machine offers three operation modes: "Manual", "Semi Auto", and "Full Auto" for user selection.

h) Safety Features: The safety door is equipped with electric and mechanical safety devices to prevent mould closing when the door is open, ensuring safe and reliable operation.

i) Blowing Functions: This machine provides two blowing functions, straight cutting, and oblique cutting.

Technical Parameters:

Basic Specifications

- Applicable materials: PE PP PVC PA...

- Max product volume: 5 L

- Number of heads: 1,2,3,4 SET

- Machine dimension (LxWxH): 3.6×2.3×2.36 M

- Machine weight: 4.9 TON

Mould Clamping System

- Mould clamping force: 90 KN

- Platen opening strokes: 180-480 MM

- Plate stroke: 300

- Max mould sizes(WxH): 400×420 MM

Extrusion System

- Screw diameter: 80 MM

- Screw slenderness ratio (L/D): 24

- Plasticizing ability (HDPE): 90 KG/H

- Screw heating stage/zone: 4 Zone

- Screw heating power: 15.85 KW

- Screw fan power: 0.28 KW

- Extrusion motor power: 30 KW

Head

- Head heating stage/zone: 10 Zone

- Head heating power: 16.5 KW

Energy Consumption

- Total machine power: 80 KW

- Oil motor power: 11 KW

- Air pressure: 0.6-0.8 MPA

- Compression air volume: 1.2 M3/H

- Cooling water volume: 0.4 M3/H

Applications:

1. Plastics Industry

Pipes, rods, and profiles: Production of PVC pipes, PE pipes, ABS rods, window and door profiles, etc.

Films and sheets: Used to make stretch film, packaging film, PET sheets, etc.

Cable sheathing: Extrusion of plastic sheaths for electrical wires and cables.

Woven bag fibers: For polypropylene fiber extrusion used in woven bags.

2. Rubber Industry

Tire treads, seals, and hoses: Continuous extrusion of rubber components.

Rubber insulation for cables: Provides enhanced thermal and electrical insulation.

3. Food Industry

Extruded snack production: Used in making puffed snacks like corn curls, rings, etc.

Noodles and pasta: Extrusion of rice noodles, spaghetti, and other starch-based products.

4. Metal Industry

Extrusion of aluminum, copper, and other metals: For manufacturing profiles, heat sinks, structural parts, etc.

5. Construction & Building Materials

Panels, flooring, roofing tiles, window frames: Production of plastic or composite building materials.

6. Chemical & Material Development

Functional material extrusion: For conductive plastics, flame-retardant materials, fiber-reinforced composites.

Laboratory-scale extruders: Used for research and development of new polymers.

7. Medical & Biotech Industry

Medical tubing: Production of IV tubes, catheters, and other medical-grade polymer tubes.

Controlled-release drug materials: Extrusion of polymers used in drug delivery systems.

FAQ:

Q: What is the brand name of the extrusion molding machine?

A: The brand name is MEPER.

Q: What is the model number of the extrusion molding machine?

A: The model number is 70FD.

Q: Where is the extrusion molding machine manufactured?

A: The machine is manufactured in China.

Q: What certifications does the extrusion molding machine have?

A: The machine is certified with CE/ISO9001:2008.

Q: What are the payment terms for purchasing the extrusion molding machine?

A: The payment terms accepted are L/C and T/T.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!