Product Description:

The Plastic Bottle Blow Molding Machine represents a state-of-the-art solution designed to cater to the needs of modern production lines, focusing on efficiency, reliability, and the production of high-quality plastic containers. This machine falls under the category of automatic bottle blowing machines, which ensures a highly efficient and automated production process. As the demand for plastic containers continues to grow globally, this machine stands as an essential piece of equipment for manufacturers in the beverage, pharmaceutical, and personal care industries, among others.

At the heart of this machine lies its Automatic Grade, which is fully automatic. This feature is integral to facilitating a streamlined production process, reducing the need for constant human intervention, and minimizing the risk of error. The automatic nature of the machine ensures that each step of the blow molding process is precisely controlled and executed, leading to consistent bottle quality and shape. This level of automation also contributes to a safer work environment, as it limits the need for operators to interact with the moving parts of the machinery.

The machine is designed to handle a Container Capacity of up to 1 liter, making it ideal for a wide range of products, from small beverage bottles to large cleaning supplies. This versatility is crucial for manufacturers who produce a variety of products and need a single machine that can accommodate different container sizes without compromising on quality or efficiency.

Powered by an Electric Motor of 7.5kW, this plastic bottle blow moulding machine offers a perfect balance between energy consumption and performance. The motor is engineered to provide the necessary power to perform the blow molding process while maintaining energy efficiency, which can result in significant cost savings for manufacturers over time. The strength of the motor also ensures that the machine can maintain consistent operation even under the demands of high-volume production schedules.

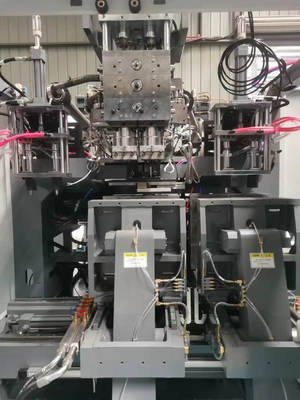

With options for a Mold Cavity that can be either Single or Double, the machine provides flexibility in terms of production output. A single mold cavity is ideal for specialized or lower-volume production runs, while a double mold cavity can effectively double the production capacity, which is a valuable feature for businesses looking to scale up their production without investing in additional machines. This flexibility allows manufacturers to adjust their production according to market demand, ensuring that they can respond quickly to changes in consumer needs.

The Plastic Bottle Blow Molding Machine is Suitable For a variety of plastic materials, including PP, PE, and PVC. This wide range of material compatibility opens up numerous possibilities for manufacturers, as they can produce bottles and containers for different applications and industries., PP for its high-temperature resistance, PE for its flexibility and durability, and PVC for its cost-effectiveness and versatility. Being able to work with these materials means that manufacturers can meet the specifications and standards required for different products and markets.

In summary, the automatic bottle blowing machine is a robust and versatile piece of bottle blowing machinery that stands out for its automatic operation, container capacity, powerful electric motor, flexible mold cavity options, and compatibility with multiple materials. As a plastic bottle blow moulding machine, it is designed to meet the challenges of modern production environments, offering manufacturers a reliable, efficient, and cost-effective solution for producing high-quality plastic containers. This machine is an investment in productivity and scalability, providing a competitive edge in an ever-evolving market.

Features:

- Product Name: Plastic Bottle Blow Molding Machine

- Max Capacity: 20L

- Auto Defleshing System: Yes

- Mold Cavity: Single/Double

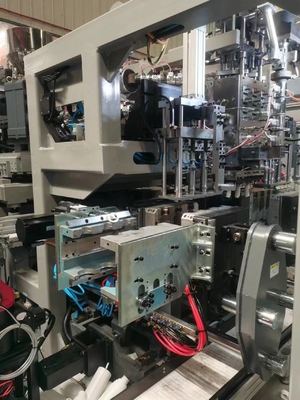

- System: Parison Control System MOOG

- Head:1-8 heads

Applications:

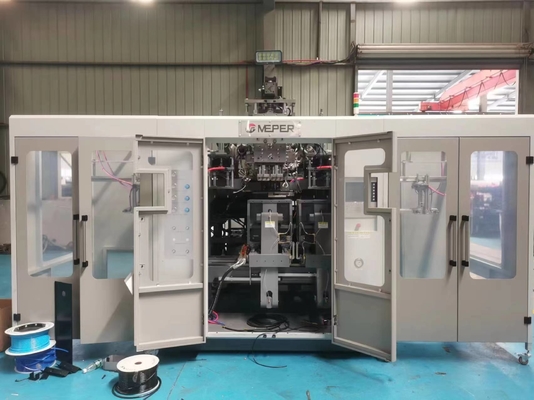

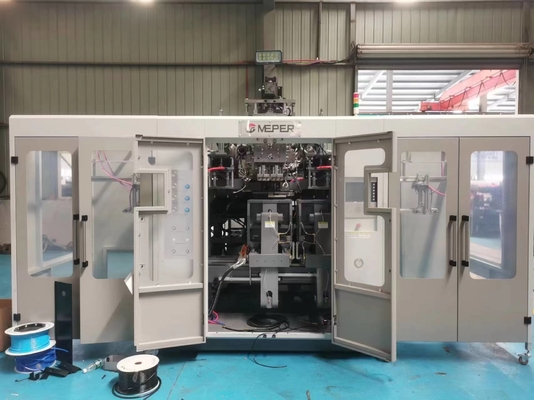

The MEPER MP100FD is an automatic bottle blowing machine originating from CHINA that is engineered to revolutionize the production of plastic containers. This sophisticated piece of bottle blowing machinery integrates state-of-the-art technology with MEPER's commitment to reliability and efficiency. With an electric motor and a maximum capacity of 20 liters, the MP100FD stands out in its ability to cater to a wide array of bottle sizes and designs, making it a versatile solution for various industries.

This plastic container blowing machine is capable of handling multiple applications and scenarios. Whether it's for producing large water bottles, chemical containers, or even smaller beverage bottles, its maximum capacity of 20 L allows for flexibility in production. The MP100FD model features a mold cavity that can be configured as single or double, thus enabling manufacturers to optimize their operations based on production requirements and boost throughput with its automatic grade functionality.

The color triple configuration of the MEPER MP100FD machine not only adds an aesthetic edge to the production floor but also enables operators to quickly identify and manage different production processes. The automatic grade of the machine ensures consistent quality and precision in each product, which is crucial for manufacturers who demand the highest standards for their plastic bottles and containers.

Application occasions for this automatic bottle blowing machine are vast, ranging from the food and beverage industry, where PET bottles for water, juices, and soft drinks are in constant demand, to the pharmaceutical sector where durable and sterile plastic containers are essential. Moreover, the MEPER MP100FD is well-suited for personal care and cosmetic products, providing elegant and reliable packaging solutions for lotions, creams, and cleansers.

Moreover, the MEPER MP100FD is a perfect fit for industrial scenarios where heavy-duty containers for lubricants, detergents, and cleaning agents are required. Its robust design ensures that the bottles produced can withstand the rigors of industrial use. The agricultural industry also benefits from this plastic container blowing machine, as it can produce large containers for fertilizers and pesticides, ensuring they are safely stored and transported.

In summary, the MEPER MP100FD plastic bottle blow molding machine is an automatic, efficient, and highly adaptable piece of equipment that is capable of meeting the diverse needs of modern bottle production. Its impressive specifications and the ability to produce high-quality plastic containers make it an indispensable asset for businesses looking to scale up their production capabilities and maintain a competitive edge in the market.

Customization:

Discover the MEPER MP100FD, a premium plastic bottle molding equipment designed to cater to your specific production needs. Originating from CHINA, this model boasts a robust Servo System, ensuring high-precision operation and energy efficiency. With a maximum capacity of 20L, the MP100FD is perfect for businesses looking to enhance their plastic container blowing machine capabilities.

The MP100FD model is not only powerful but also versatile, handling container capacities up to 20L with ease. The integration of a Parison Control System MOOG elevates the precision of wall thickness distribution, making it a top-tier choice for those in need of a reliable plastic bottle blowing machine.

Operating on a strong 7.5kW Electric Motor Power, MEPER's plastic container blowing machine ensures that your production is not only efficient but also cost-effective. Choose MEPER's MP100FD for an advanced solution to your plastic bottle production requirements.

Support and Services:

Our Plastic Bottle Blow Molding Machine is designed with both performance and reliability in mind, ensuring that you can produce high-quality plastic bottles efficiently. To make sure that you get the most out of your machine, we offer a comprehensive suite of technical support and services that include:

Installation and Setup: Our team of skilled technicians will assist you with the proper installation and setup of your Plastic Bottle Blow Molding Machine to ensure that it is calibrated and functioning correctly from the start.

User Training: To help your staff get up to speed, we provide detailed training sessions covering the operation, maintenance, and safety procedures associated with the machine.

Maintenance Services: Our maintenance services are designed to keep your machine running smoothly. This includes periodic checks, routine cleaning, and the timely replacement of wear and tear parts.

Technical Consultation: Should you have any questions or need advice regarding the machine's operation or optimization, our experts are available to provide you with the necessary technical consultation.

On-site Support: If you encounter any complex issues that cannot be resolved remotely, we can dispatch our technicians to provide on-site assistance and troubleshooting.

Remote Diagnostics: With the help of modern technology, we can offer remote diagnostics to quickly identify and resolve issues without the need for on-site visits in many cases.

Replacement Parts: We supply a full range of replacement parts for your Plastic Bottle Blow Molding Machine, ensuring that you have access to high-quality components when needed.

Software Updates: As improvements and updates are developed, we provide software updates to enhance your machine's functionality and efficiency.

Our commitment is to provide you with the support and services you need to maintain optimal performance and maximize the lifespan of your Plastic Bottle Blow Molding Machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!